25 YEARS of experience in manufacturing modern electronic modules for complete systems made us a reliable partner for various industries, from consumer electronics through mobile and automotive technology to the Hi-Tech IT / T industry.

We have certified Quality Management Systems according to IATF 16949 and ISO 9001, Environmental Management Systems according to ISO 14001, OSH Management System according to ISO 45001.

Production facilities

Our Production facilities

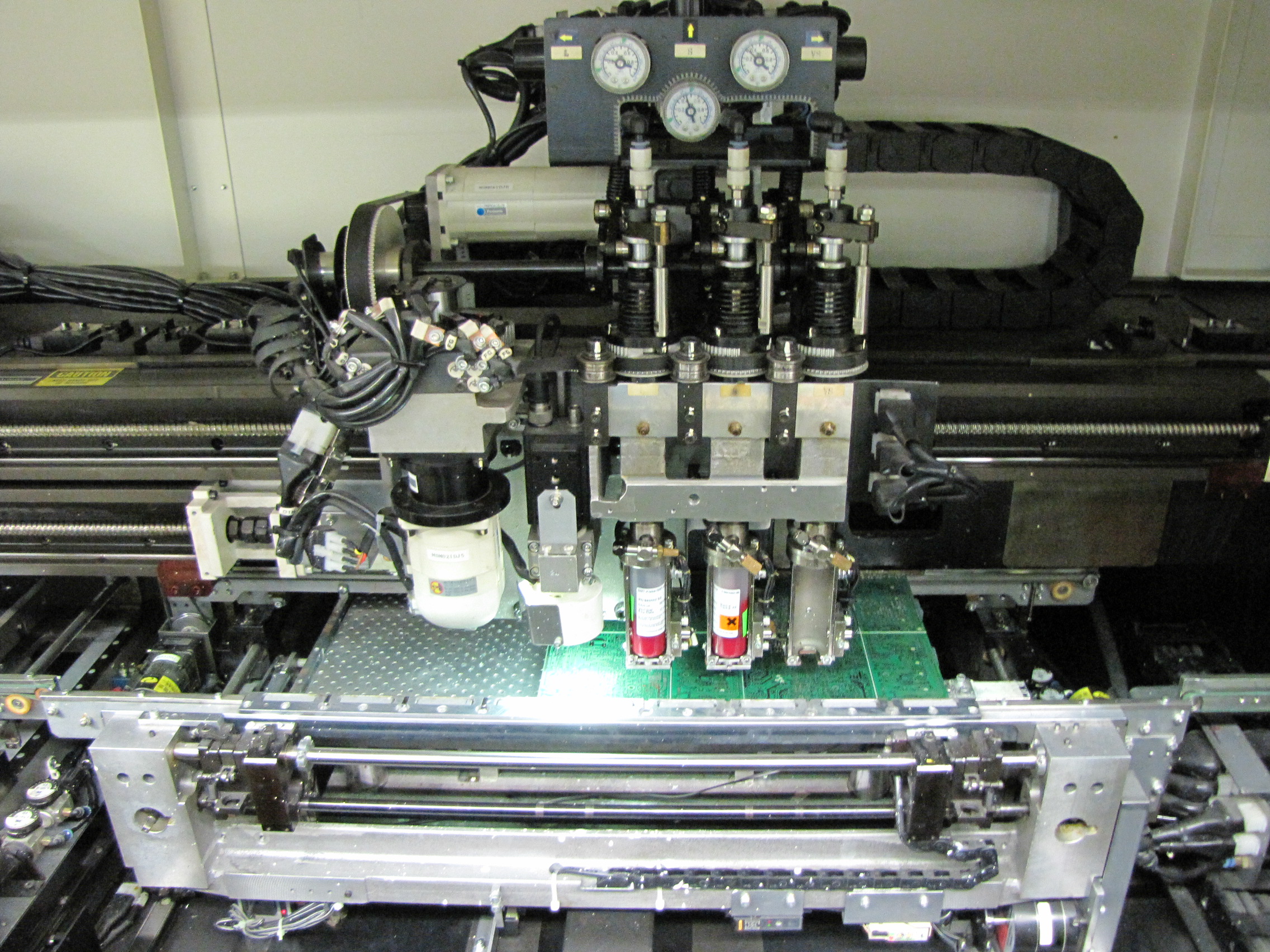

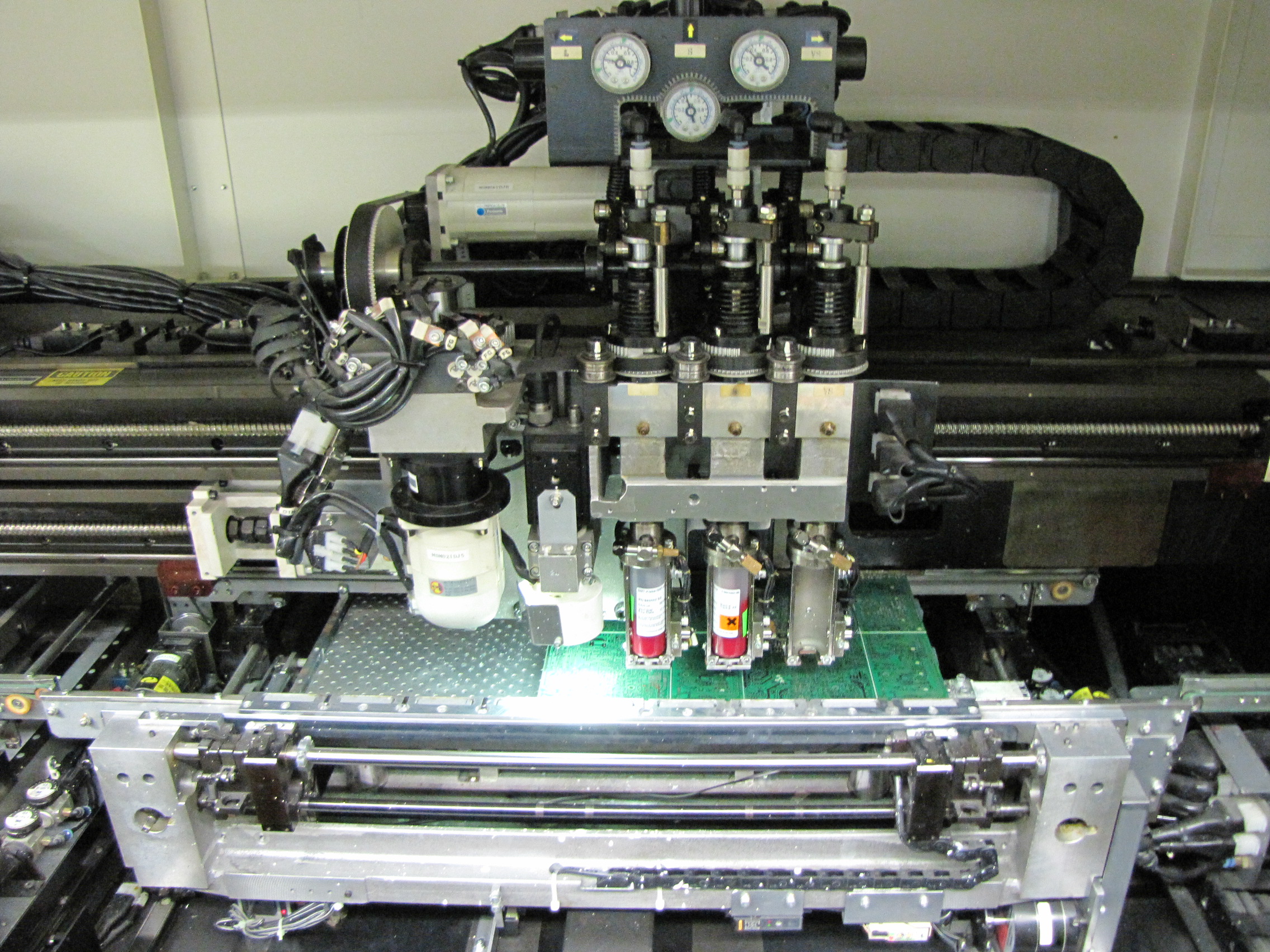

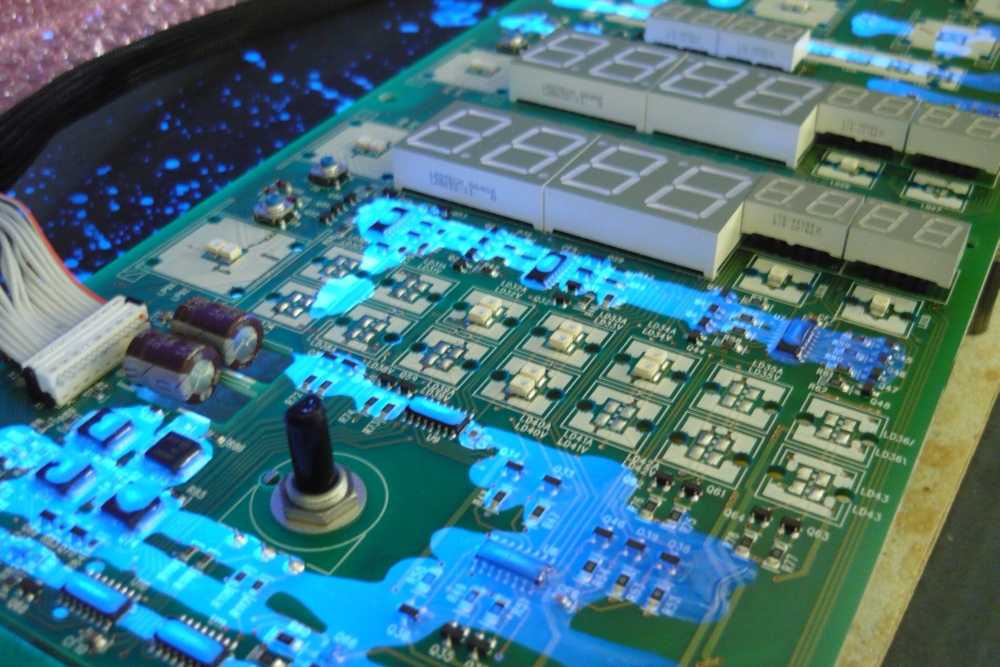

SMT assembling

SMT assembling

- average capacity 34,000 components per hour, under maximum load all lines 138,000 components per hour

- various components assembling from size 0201, finepitch, μfinepitch, BGA, μBGA

- 3-shifts working avaliable

- 1 assembly lines equipped with SIEMENS Siplace (S20, F4)

- 3 assembly lines equipped with PANASONIC (MSR, MPA)

- 2 assembly lines equipped with PANASONIC (MSH2, MV2F)

- reflow owens ERSA Hotflow 7, 9 > 7-9 zones owens and SIEMENS ReHm V8 Nitro

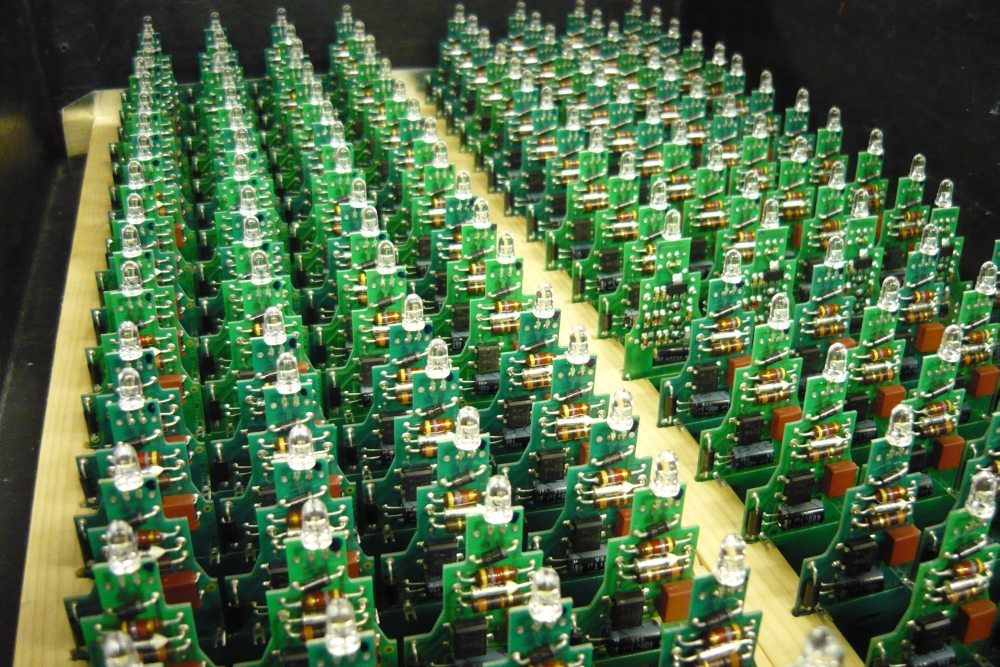

THT Assembling

- 3 conveyer manual assembly lines

- 3 automated soldering machines, Pb + Pb Free (2xATF, 1x SEHO)

- ATF soldering using a nitrogen atmosphere

- 1x selective soldering (Inter Select)

- 3-shifts working available

Laser (engraving and labelling)

Automatic varnishing machine

Capability range

Capability range

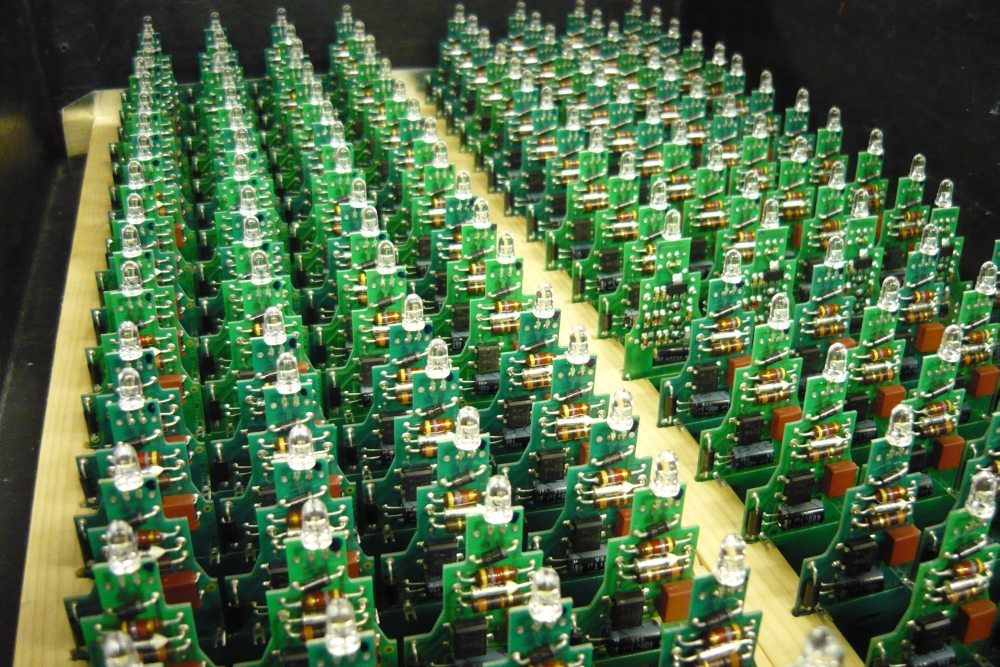

Parts shaping and forming

Parts shaping and forming

- Forming various shapes lead components with usage of automated shaping machines

- Cutting the length of the lead components

- Assembling flat cables, crimping etc.

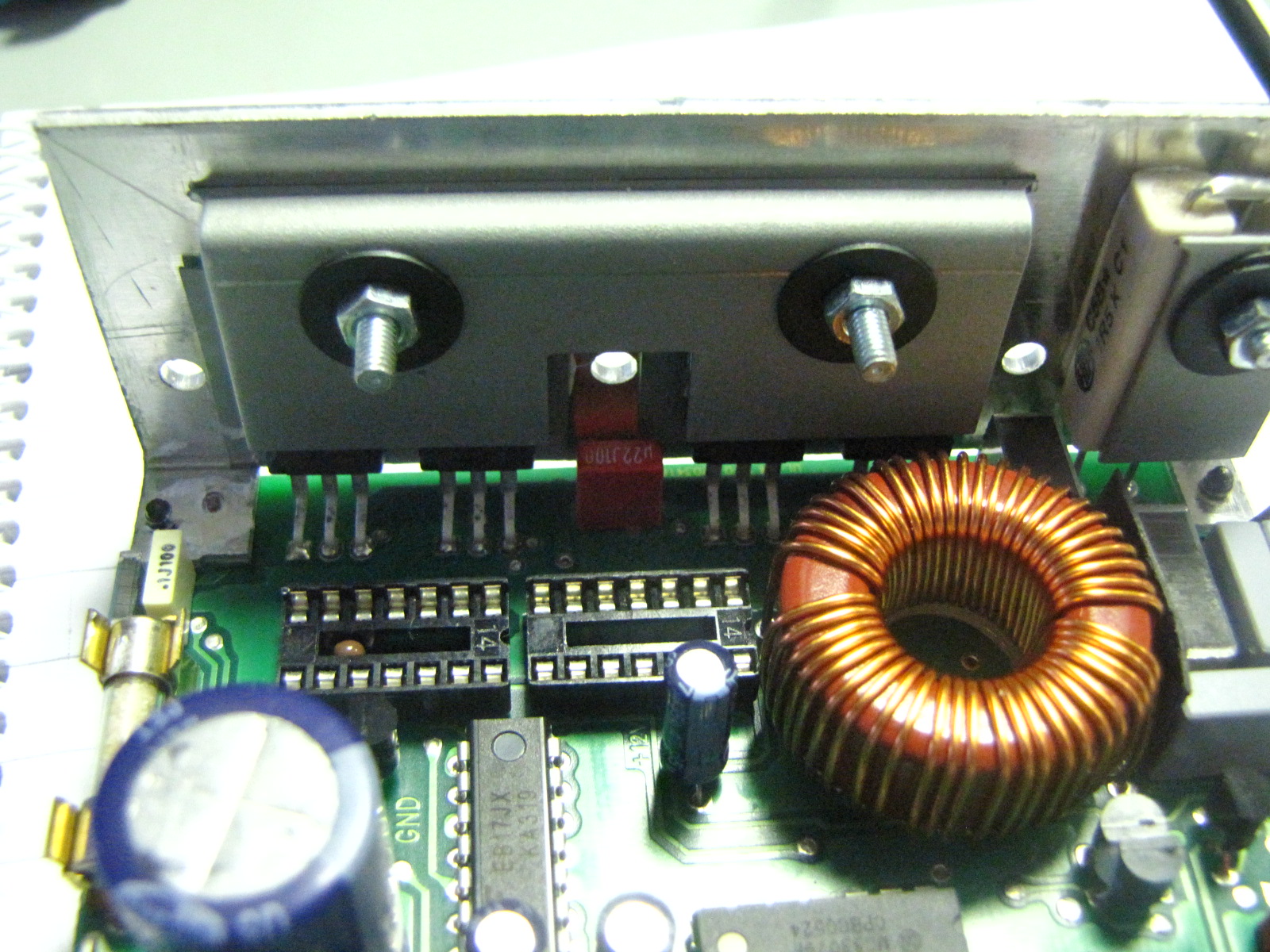

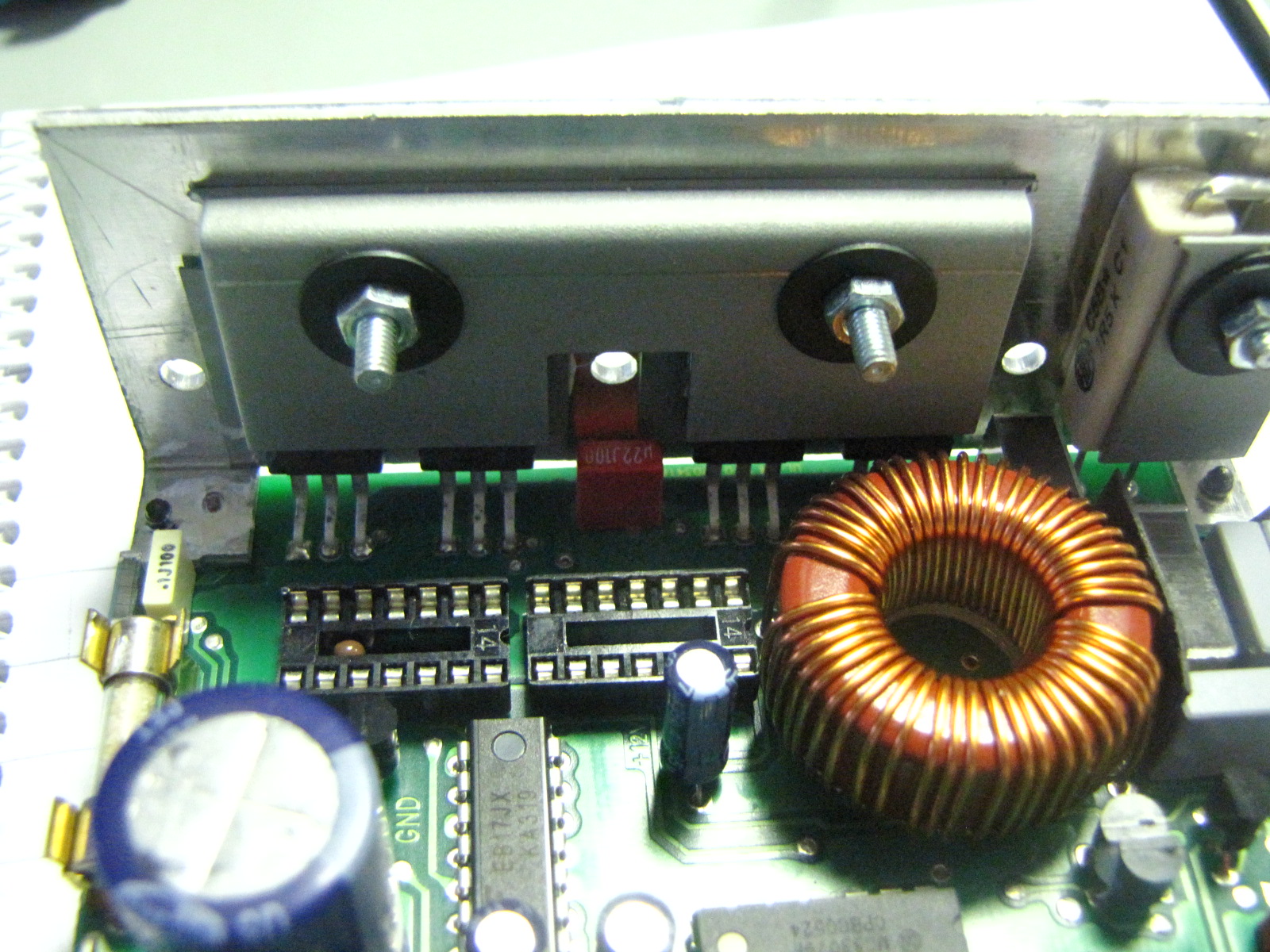

Heat-sink assemblies

- Various type of heat-sink assemblies mounting with heatconducting paste

- Components screwing and bonding with precision screwdrivers

- Checking of the tightening torques

- Fixing screws against loosening

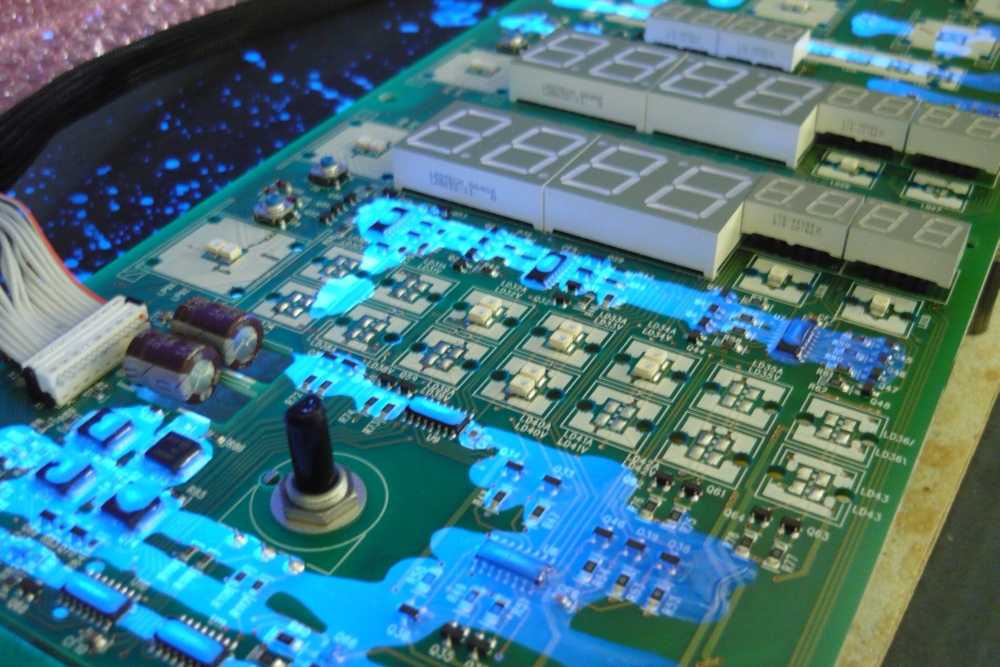

AOI – automatic optical inspection

- Guarantee of 100% optical check of correctness and accuracy of automatic components

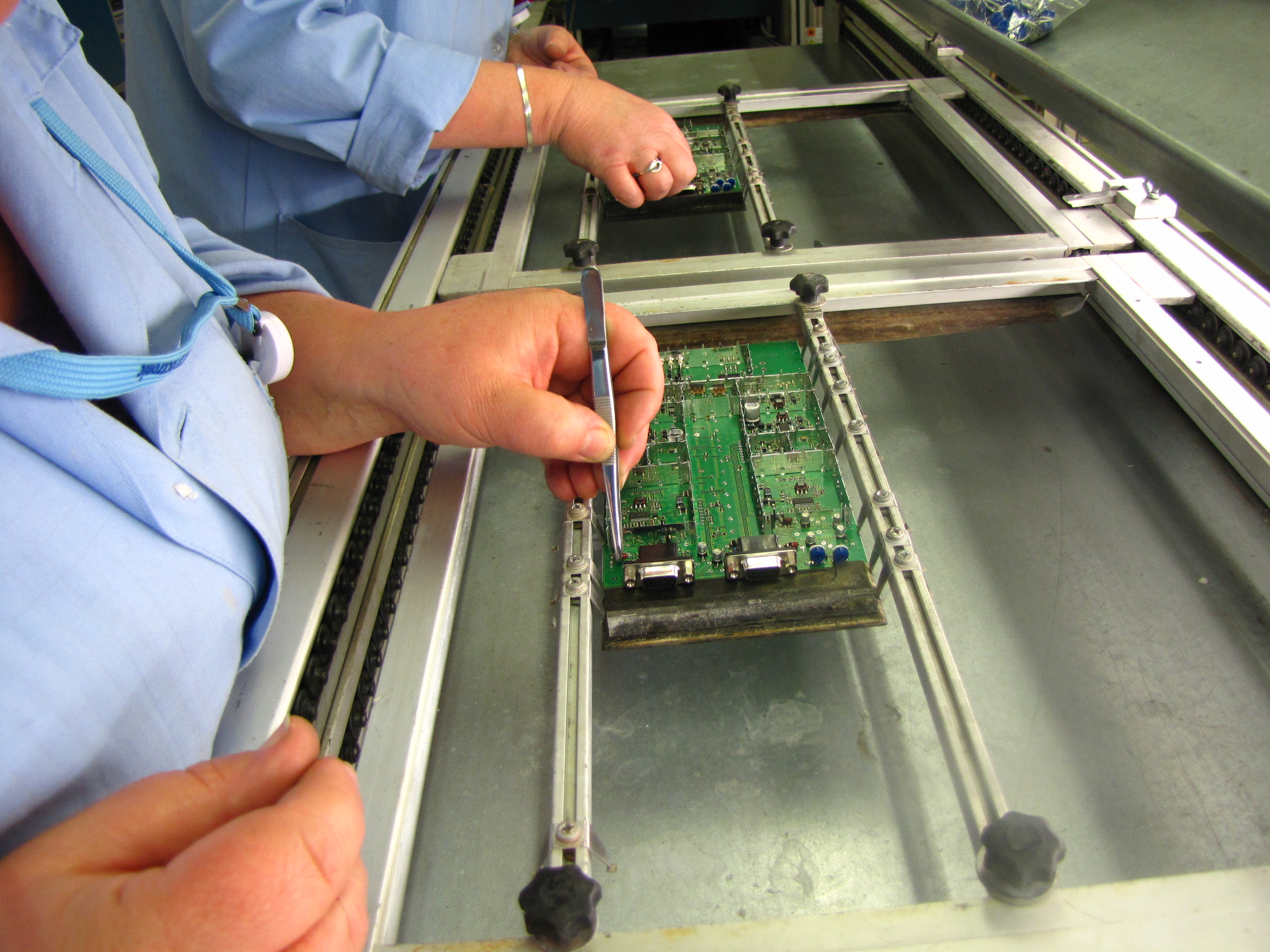

Thru-hole components assembling

- Assembling of large and sophisticated electronic systems under attendance of our skilled specialists

- Manual soldering of difficult components

SMD assembling

- Using curing process (glue dispensing + curing owen)

- Using reflow process (solder paste + reflow owen)

Wave soldering

- Automatic wave soldering technology under nitrogene

- Guarantee of unleaded soldering technology (RoHS)

- Specific shape products soldering using solder frames and solder masks

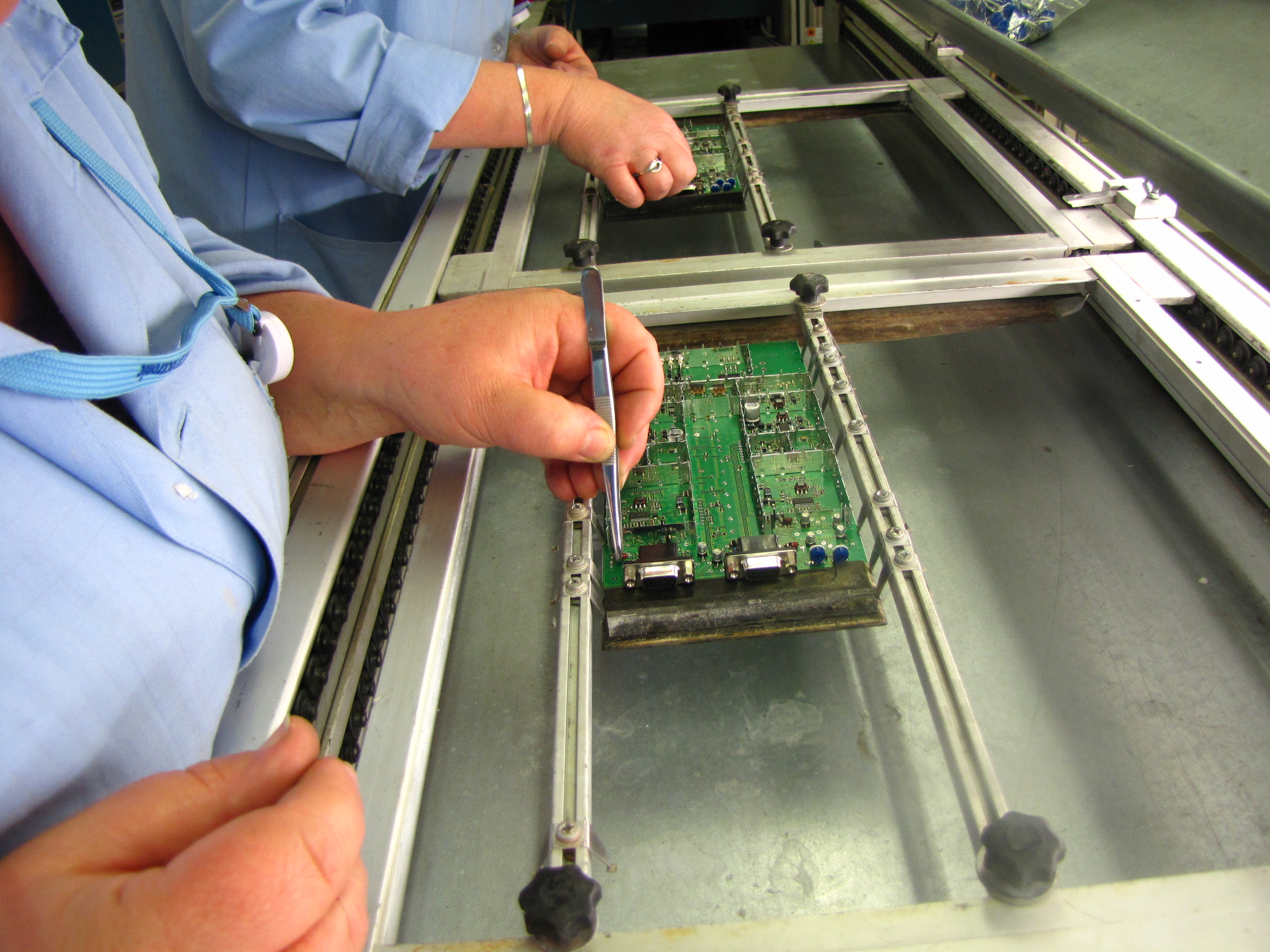

Functional and ICT testing

- Preparation and design of testing devices and units based on output parameters of device and test requirements

- Usage of dedicated and universal testing devices

- Own development department of testing devices

- IC test products through needle field at device TR5001T and IC Test by "flying needle" at device SPEA

- Wide scale of functional tests by customer needs

- High voltage tests of single components

- Burn-in tests

- System of tracebility, which guarantee execution of all demanded tests with logfile records

Special Technologies and services

Special Technologies and services

Varnishing

Varnishing

- Automatic varnishing application on PCB for purpose of protection against the air humidity using automatic varnishing machine

- Hardening and drying varnishing masks

Potting

- Automatic soaking of PCBA in plastic or metal housing using epoxide or resin based substances

- Guarantee of exact automatic batching by devices with laser sensors

Special SMT technologies and processes

- Washing PCB´s in special full automatic mashine Injet® 388-MCD

- storage of MSL material in nitrogen atmosphere in 5% humidity - device ASVS 1200M

- drying components in special drying owen

- mixing of solder paste in GLICHN device

- system of tracebility via wireless server

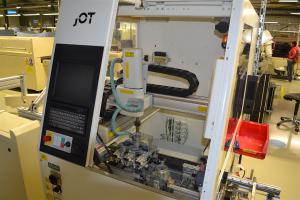

- dividing of PCB´s at JOT device

- lead or lead free soldering

Special SMT technologies and processes

- dividing of PCB´s at CNC cutter

- Producing of solder masks

- production of various products at CNC machine

Laser engraving

- Descriptions, codes and logos engraving using automatic LASER device TRUMPF

Labels printing

- Thermo-print-identification (BCR,typical) labels printing using thermo-printers

- Various types of labels printing (paper,plastic,etc.)

IC circuits programming

- Preparation and uploading programs in the IC components

Development

- Optimalization proposals and development

- Development and production of plastic and metal housings

- Development and production of packaging and product user´s manuals

- Prototypes manufacturing

Co-operation wtih sister companies

- Printed Circuit Boards production

- Development of testing and control devices

Final assembly

Final assembly

- Assembly of electronic components and parts (PCBA) with plastic and metal parts

- Product finalization, programming, testing and housing

- Design of optimal packaging for safe transport of products

- Products packaging for end-user distribution chain

Products portfolio

Products portfolio

We produce also:

We produce also:

- Telecommunication equipment

- Mobile chargers

- Modules for use in explosive atmospheres

- Automotive modules

- Printer controllers

- Door speech systems

- Components GSM/UMTS

- Components GPS

- Alarm modules

- Modules for satelite devices

- Components pre Hi-Fi a TV devices

- Medical devices

- ... and soon also Your products!

Photo Gallery

Photo Gallery

SMT assembling

SMT assembling